Dipoles

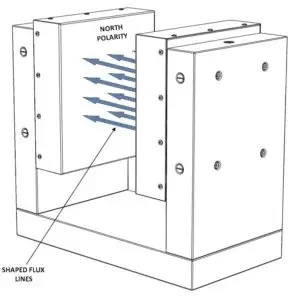

Dipoles consist of a pair of magnets across a gap. They come in many shapes/sizes and the magnets are usually mounted on a steel frame (also called a yoke) for magnetic efficiency, magnetic shielding and/or mechanical strength. Dipoles are used when an application requires a specific magnetic field strength and uniformity over a specific volume. Pole pieces are sometimes used to enhance uniformity within the gap.

At Dexter, we have built hundreds of different types of dipoles, each optimized for a particular application. Field strengths have ranged as high as 3.0 Tesla (30,000 Gauss). Generally, higher fields are associated with small air gaps. Higher uniformity is generally associated with large air gaps.

Dipoles are used to:

- Calibrate/initialize magnetic sensors

- Erase computer hard disk drives

- Orient thin layers of magnetic material as they are deposited as thin films

- Divert or focus beams of energized particles

We’ve used the dipole principle in these designs:

DESIGN HELP

When working with our engineering group, you might be asked:

- What is the minimum magnetic field strength required?

- How large a volume?

- How large can the dipole be, does it have to fit within other devices?

- Will the dipole be exposed to elevated or cryogenic temperatures?

- Will the dipole be exposed to vacuum or corrosive gases/fluids?

- Do you need the polarity marked?

MATERIALS

Neodymium Iron Boron and Samarium Cobalt often are used when large magnetic fields are required. Hard ferrite is used if cost is more important than large magnetic fields. Alnico is generally used if dipole is to be used in high temperature environment (>300°C).

FAQS

What is the strongest magnetic field Dexter can create? To date, the strongest magnetic field we have created is 3 Tesla (30,000 Gauss) across a 5mm air gap.

How large can the magnet be? Our largest magnet to date is cube shaped, approximately 2 meters per side.

Is it possible for a dipole to work in an oven? Alnico materials typically are used for high temperature applications. If Alnico material is not strong enough, the dipole should be designed around the exterior of the oven.

PROTOTYPES

Feasibility study required: no.

Typical design time: 1-2 days

Typical material acquisition & build time: Two weeks, if material is available. Six to eight weeks, if material is not available.

Halbach/Stelter Arrays

Halbach and Stelter array dipoles are used where very high magnetic fields are required. Halbachs are used when performance/uniformity are key requirements. Stelter dipoles are cost effective, but do not produce as uniform fields.

Klaus Halbach, a professor with the University of California’s Lawrence Berkeley Labs, was an innovator in the application of permanent magnets to accelerator and synchrotron light projects around the world. The principle behind his innovative work is superposition. The superposition theorem states that the components of force at a point in space contributed by several independent objects will add algebraically.

Applying the theorem to permanent magnets is possible only when using materials with coercivity nearly equal to residual induction. While ferrite magnets have this characteristic, it was not practical to use the material this way because simple Alnico magnets provided more intense fields at a lower cost. The advent of high residual induction rare earth magnets such as Sm-Co and Nd-Fe-B made the use of superposition practical and affordable. These materials allow developing intense magnetic fields in small volumes without the energy requirements of electromagnets. The disadvantage for electromagnets is the space occupied by electrical windings, and the need to dissipate the heat generated by the coils.

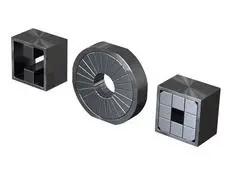

While Dr. Halbach pursued “high end” applications of superposition, Dexter’s Dick Stelter used the theorem in commercial applications. Halbach taught the use of “magic ring” dipoles to develop intense fields in a circular aperture. In this device trapezoidal magnets are assembled to form a ring. The orientation of each trapezoidal magnet is such that there is a continuous rotation of the magnetic vector in each half of the ring, and for an infinitely long ring, field strength in the aperture is proportional to the natural log of the ratio of OD to ID.

Stelter arrays use the minimum number of rectangular magnet shapes to reach the desired results in a rectangular aperture. For a stelter array, the relationships are similar, and the internal field is proportional to the natural log of the outer periphery to inner periphery ratio. Using rectangular shapes also permits “flux bottling” to shape the internal field. Highly uniform magnetic fields of over 2-3T can be routinely generated in a range of air gaps, and Dexter applications based on the patented Stelter Array include dipoles for NMR/MRI, “open” NMR, mass spectrometers, sputtering magnetrons, hard disk erasers, miniature rotary actuators, bulk erase tools and many more.

TYPES

Halbach and Stelter array dipoles are used where very high magnetic fields are required. Halbachs are used when performance/uniformity are key requirements. Stelter dipoles are cost effective, but do not produce fields as uniform as other dipoles.

MATERIALS

Neodymium Iron Boron and Samarium Cobalt are typically used. Hard ferrite materials can also be used but magnetic field output is reduced. Because of the large internal demagnetization fields, Alnico is rarely used for Halbach/Stelter dipoles.

Aluminum is used for round Halbach dipoles. Steel is used for square dipoles.