Dexter Magnetic Technologies has designed and produced a large variety of permanent magnet static field sources for MRI/NMR applications, some based on our current quadrature magnet patents and others so unique that patents have been applied for.

Magnetic Resonance Imaging (MRI) was known as Nuclear Magnetic Resonance (NMR) until the ‘nuclear’ connotation became unpopular, but both names denote the Magnetic Resonance (MR) principle involved. Besides the MRI machines one finds in hospitals, magnetic resonance devices are commonly in devices used to ensure proper chemistry / material mix, such as equipment used to monitor quality of asphalt.

MR detects an atom’s gyromagnetic ratio, the ratio of the magnetic dipole moment, due to nuclear spin, to the mechanical angular momentum, to discriminate between elements. Almost every element in the periodic table has an isotope with a non zero nuclear spin, but to be useful the isotope must also be abundant in the volume being analyzed. Therefore, the nuclei of interest in MRI of the human body and other living organisms are those of hydrogen, carbon, nitrogen, sodium, phosphorus, potassium and calcium.

MRI system components include:

- a magnetic dipole to establish a static magnetic field,

- a gradient coil,

- an RF coil to produce an alternating magnetic field at 90° to the static magnetic field, and

- an antenna coil.

- In operation, protons in the sample volume are oriented by the static field, and caused to precess by the alternating RF magnetic field. When power to the RF coil is turned off, the magnetic moment of the protons realigns with the static magnetic field. The energy change involved in realignment of the magnetic moments is measured as a small RF signal by the antenna coil and a Fourier transform of signal frequency and phase produces data used to construct a distinctive image.

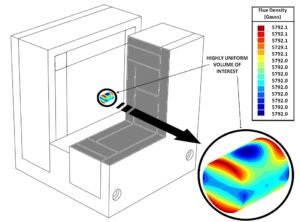

Data for each atom/molecule depends on the atoms present and the surrounding molecular structure. This allows MR to differentiate liquids from one another, or a liquid from a solid, making the technique useable for quality control processes. The static magnetic field strength required depends on the element being imaged and the desired resolution. Fields as low as 0.02 T have produced useable hydrogen images, but 0.08 – 0.1 T is more common for quality control work. Higher flux densities are needed for greater resolution and other elements, so laboratory superconducting systems with fields of 1.5 to 4.7 T are in use. Magnetic field strength uniformity also affects resolution, so magnetic field static sources with uniformity of +/- 0.0001 mT are trimmed with trim coils, magnetic shims or trim magnets to obtain uniformity over the sample volume in the parts per million range.

A permanent magnet source substantially reduces the power required by an MRI/NMR system and allows portability. However, higher resolution translates to higher flux density and uniformity across the sample, and this increases size and cost exponentially, so it is important to minimize the sample volume and be realistic about the desired resolution when designing a system.

MATERIALS

We often use sintered Neodymium Iron Boron magnet material for its high energy. Samarium Cobalt magnet material is used when there is elevated temperature.