Configurations

Linear motors come in three configurations. These are U-channel, flat-type, and cylindrical (tubular). Voice coil motors can also generate linear motion; they are made in different geometries as well. The linear motors have different characteristics because of the configurations, in force magnitude, speed, acceleration / deceleration, motion smoothness, leakage field, and cost.

Dexter can design, manufacture and deliver custom linear motor solutions.

Cylindrical

• 3-phase windings typically, with brushless commutation using Hall effect sensors

• Magnetic leakage: Medium-High

• Points of support: Only at both ends

• Limit of length due to deflection

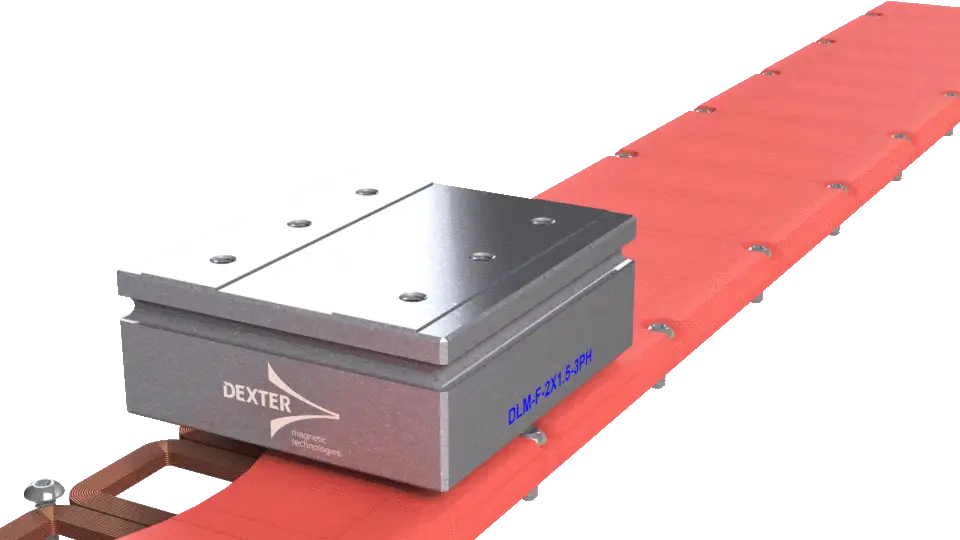

Flat

• Ironless flat motors – smooth velocity control

• Slotless-iron flat motors – for higher force output

• Slotted-iron flat motors – for even higher force output

• Cogging force can be reduced by skewed magnets

Attractive force between “forcer” and magnet track can be used advantageously as preload

U-Channel

• Two parallel magnet tracks facing each other, seated in U-shaped channel

• “Forcer” (coil windings) supported by bearings between magnet tracks

• Typically 3-phase, w/ brushless commutation

• Forcer is ironless; low mass; high acceleration; smooth linear motion

• Magnetic leakage: Low

Can be staged to increase length of travel