How MOKE Measurements Are Used in Semiconductor Manufacturing Metrology

Principle Applications of Magneto-Optical Kerr Effect (MOKE) Measurements

The Magneto-Optical Kerr Effect (MOKE) is a powerful technique used to study the magnetic properties of materials. In semiconductor manufacturing, MOKE measurements are particularly useful for analyzing thin magnetic films, magnetic domains, and other magnetic structures at the nanoscale. These measurements are essential for the development and quality control of magnetic materials used in various semiconductor devices, such as magnetic random-access memory (MRAM) and spintronic devices.

How MOKE Measurements Are Used in Semiconductor Manufacturing Metrology

Characterization of Magnetic Thin Films: MOKE is used to characterize the magnetic properties of thin films, including coercivity, magnetic anisotropy, and magnetization reversal processes. This is critical in the development of magnetic layers for spintronics and other advanced semiconductor applications.

Magnetic Domain Imaging: MOKE can be employed to image magnetic domains in materials, providing insights into the behavior of magnetic structures at the microscale. This helps in optimizing the design and performance of magnetic devices.

Quality Control: MOKE measurements are used for quality control in the fabrication of magnetic components, ensuring that the magnetic properties meet the required specifications.

How MOKE Measurements Work

MOKE measurements are based on the interaction between polarized light and a magnetized material. When polarized light reflects off the surface of a magnetized material, the polarization of the reflected light is altered in a manner dependent on the magnetization direction. This change in polarization is known as the Kerr effect.

- Polarized Light: A beam of polarized light is directed at the surface of the magnetized material.

- Interaction with Magnetic Material: As the light reflects off the material, the magnetic field of the material affects the polarization state of the light. The magnitude and direction of this effect depend on the orientation and strength of the material’s magnetization.

- Detection: The reflected light is analyzed to measure the change in polarization (rotation and/or ellipticity). This change provides information about the magnetic properties of the material.

Role of Magnetics within the Magnetic Field Generators for MOKE Measurements

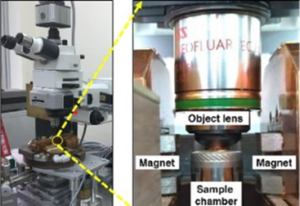

Magnetics play a crucial role in MOKE measurements by providing the magnetic fields necessary to magnetize the sample under study. These fields are typically generated by electromagnets or permanent magnets, depending on the specific MOKE setup.

Magnetic Field Generation: The magnetic field generators must create a uniform and controllable magnetic field across the sample. This field is necessary to align the magnetic domains in the material, enabling the measurement of the Kerr effect.

Field Direction Control: In many MOKE experiments, it is essential to vary the direction of the magnetic field to study the material’s response to different magnetization directions. This requires precise control over the magnetic field vector.

Critical Aspects of Magnetic Component Design

- Field Strength and Uniformity: The magnetic field must be strong enough to fully magnetize the sample but also uniform across the measurement area. Non-uniform fields can lead to inaccurate measurements of the Kerr effect.

- Precision and Stability: The magnetic field must be stable over time, with minimal fluctuations, to ensure that the MOKE measurements are accurate and repeatable. High precision in field strength adjustment is also necessary to study the magnetic properties at different field intensities.

- Electromagnet Design: If electromagnets are used, the design must ensure efficient field generation with minimal heat generation. The coil design, core material, and power supply must be optimized for performance and reliability.

- Magnet Placement and Geometry: The placement and geometry of the magnets are critical to achieving the desired magnetic field configuration. For example, Helmholtz coil arrangements are often used to create highly uniform fields in a specific region.

- Material Selection: The magnetic materials used in the field generators must have high magnetic permeability and low hysteresis loss to ensure efficient field generation. The materials should also be stable under the operating conditions to maintain consistent performance.

MOKE measurements are a key tool in semiconductor metrology for studying the magnetic properties of materials. The design and optimization of the magnetic components used in these measurements are critical to achieving accurate and reliable results. By providing the necessary magnetic fields with high precision and stability, these components enable detailed analysis of magnetic thin films and structures, supporting the development and quality control of advanced semiconductor devices.

Magnetic system design and engineering is a specialized discipline. The performance considerations of MOKE measurement equipment require expertise that comes from a dedicated focus on magnetic materials and properties and how to properly design assemblies for their magnetic purpose. Developmental costs and time-to-market can be significantly reduced by working with partners like Dexter Magnetic Technologies, who focus on magnetics and bring decades of experience designing, engineering and manufacturing to the table. Contact Dexter today and find out how we can help with your next MOKE project.